PACO•CLUTCH™:

A SINGLE COMPONENT, CONFORMABLE "CLUTCH" FILM PACKAGE FOR PCB "CAP" LAMINATIONS

OVERVIEW

PACO•CLUTCH™ is a two-side releasable film, engineered specifically for use by PCB Multilayer manufacturers that laminate etched copper laminate cores, in place of copper foil. In the outer layer lamination process, this state-of-the-art product performs a dual purpose in the production of Cap Layer constructions:

- First, PACO•CLUTCH™ decouples the outer-layer etched core from the separator plate during PCB lamination at temperatures up to 425°F (218°C) for up to 2 hours

- Simultaneously, PACO•CLUTCH™ doubles to effectively achieve the required "Clutch Effect" that is attributable to the degree of conformability designed into this .011" (279µ) thick product.

This single unit package is easy to handle and provides a new, but proven, alternative for Cap Layer processing which depends on this "Clutch Effect™". PACO•CLUTCH™ controls and improves flow characteristics of pre-preg and facilitates consistent and improved registration of layers and enhanced dimensional stability. PACO•CLUTCH™ is superior and more cost-effective for these intended purposes.

LAMINATION PROCCESS ADVANTAGES

- Ease of handling single component which is .011" (279µ) thick

- Reduced contamination and debris in lamination area

- Tooling pins are not impinged upon- PACO•CLUTCH™ can be pre-tooled

- Easy clean-up and tear down

- Improved clutch effect-flow characteristics of PACO•CLUTCH™ are engineered for performance

- Inner-layer registration is improved and more consistent

- Predictably low X & Y axis shrinkage

- Suitable for operating temperature up to 425°f (218°c) for up to 2-hours

- No embedded impurities: essentially inert, no outgassing, no plate residues, no vacuum system contamination

- Environmentally friendly: no ozone depleting chemicals, no fluorine

WHAT PACO•CLUTCH™ REPLACES

Until now, lamination of individual copper-layered components required the deployment of a conventional "clutch" package consisting of 2-ply's of pre-preg sandwiched between one ply of unsupported release film on each side. This became the standard used as the decoupling function required during Cap laminations but not without problems. This technique presents challenges to the PCB Manufacturer to achieve acceptable yields. Controlling contamination from using pre-preg and the functional performance of the pre-preg due to age which creates scaling inconsistencies are common rejection issues. The marginal conformance of this standard package can affect resin flow negatively and does not compensate for the X-Y movement of the double-sided Cap Layers used on the outside board. Furthermore the additional labor costs implicit in handling three process materials affect costs and scrap rates.

PACO•CLUTCH™ minimizes issues like contamination and inconsistent scaling simply by eliminating the need for prepreg as a "clutch". Overall improved Inner Layer Registration with consistency is achieved which ultimately improves product yields and reduces processing costs and scrap.

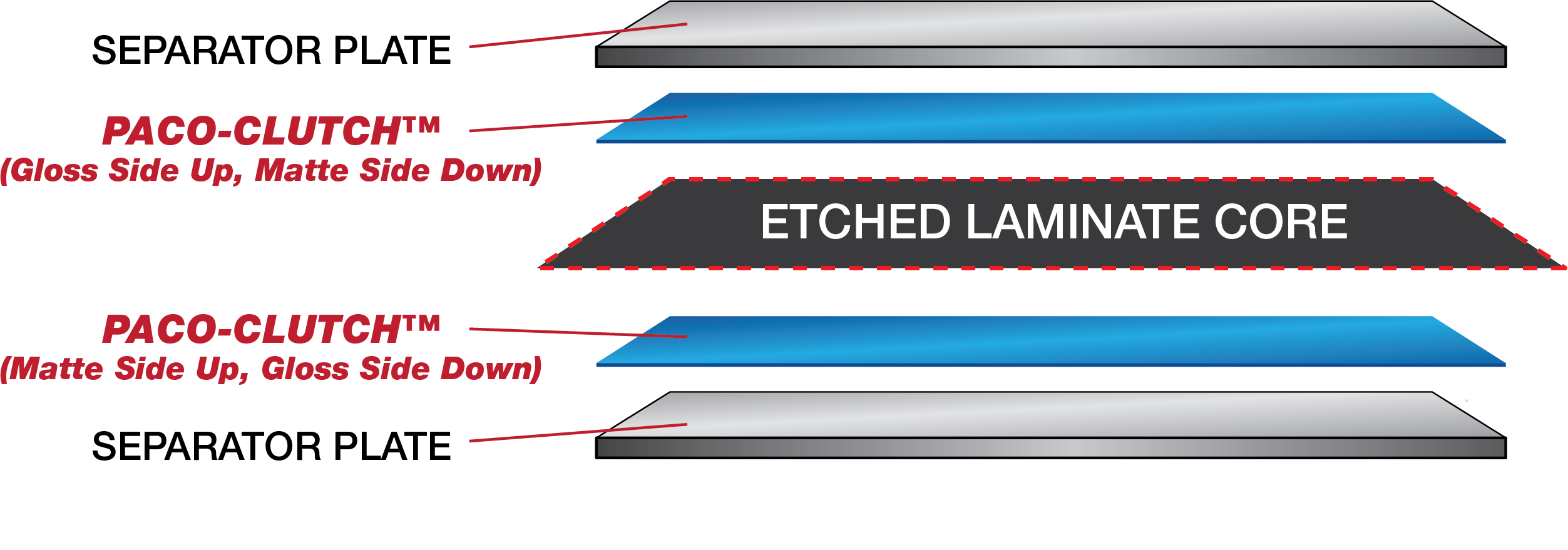

RECOMMENDED LAMINATION LAY-UP

DESCRIPTION

- Film thickness: .011" (279µ) for ease of handling

- Both sides of the film have a release function that's easy to correlate to its proper placement and position in the lay-up: Matte side - placed adjacent to the etched panel core and Glossy side - placed adjacent to the separator plate

- Rated to perform up to 425°F for up to two hours

- All Pacothane® Release Film products are manufactured in accordance to our quality standards which guarantees unparalleled performance. All manufacturing and fabrication operations are performed in house offering total supplier control and accountability

AVAILABILITY

PACO•CLUTCH™ film is available in custom-made sheet sizes, tooled if needed to customer specifications. The complete line of Pacothane® products is available from leading local distributors around the world who offer "just in time" delivery from local stocks.

SAFETY