PRESSPROBE™ TEST:

A DIAGNOSTIC TOOL TO VIEW HIGH AND LOW PRESSURE DISTRIBUTION

OVERVIEW

A PRESSPROBE™ TEST provides a quick, simple and accurate in-house procedure for checking for "high" and "low" pressure zones due to (1) press platen misalignments or (2) the design configuration (pads, high density circuitry, ground planes, etc.) of the circuit board itself. Pressures, distributed unevenly, can lead to circuit board manufacturing problems and rejects.

Implementation of a PRESSPROBE™ Test will help the laminator view potential pressure-related laminating problems even before they occur.

A PRESSPROBE™ Pressure Testing Kit contains two separate rolls of testing film. These pressure-sensitive films react together to convert pressure into a measurable color hue or density and provide a graphic representation or "picture" of both the distribution and amount of pressure across the area being tested.

LAMINATION PROCESS ADVANTAGES

- A PRESSPROBE™ TEST can be used routinely to check press platens for parallelism

- A PRESSPROBE™ TEST provides an accurate way to pinpoint where and how pressure is distributed across the surface of the circuit board. The laminator can easily identify the presence of "high and low" pressure zones prior to actual lamination, which can impact scrap rates

- A PRESSPROBE™ TEST can show uneven pressure distribution across the nip rollers of a Dry Film Laminator and can detect imperfections on the nip rollers themselves. PRESSPROBE™ testing can also highlight possible surface patterning on inner-layers (due to glass style) and therefor can characterize the possible affect that such irregularities may have in connection with the imaging of fine-lines

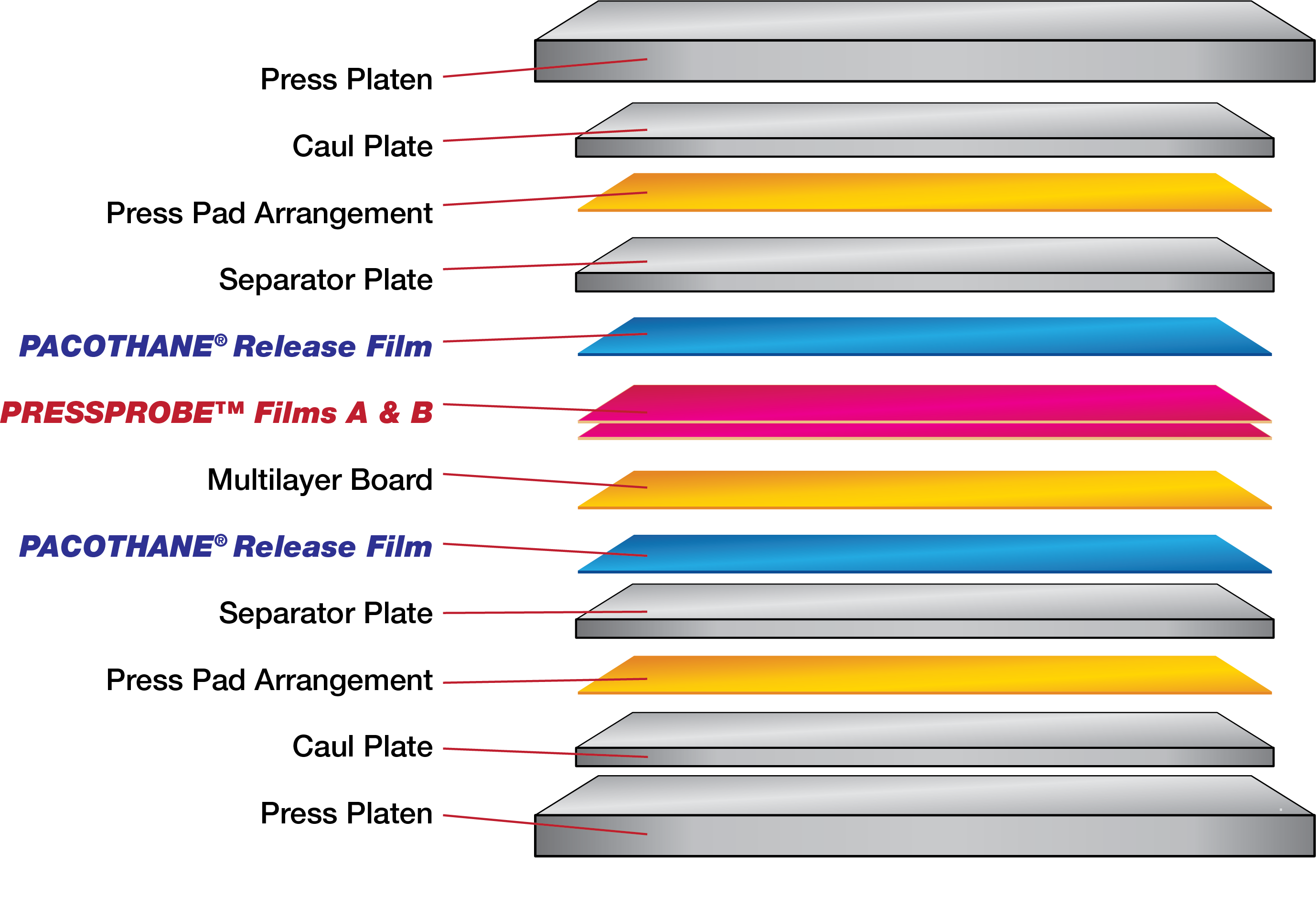

RECOMMENDED LAMINATION LAY-UP

AVAILABILITY

PRESSPROBE™ is available as a boxed kit 10.5" wide x 66' long. The complete line of Pacothane Technologies products is available from leading local Distributors Worldwide who offer "Just in Time" delivery from locally–available stocks.

METHODOLOGY & TEST PROCEDURE

- Select the suitable PRESSPROBE™ Pressure Testing Kit (consult your sales representative for advice) for the pressure range to be tested

- In each kit are two components an "A" (Black Package) and "B" (Blue Package), Cut two equal lengths of both PRESSPROBE™ A and B films to the exact size of the multilayer laminate. Since each film component (A&B) is only 10.5" (270mm) wide, it may be necessary to butt two lengths together to cover the entire test area. Each film should be handled with care and should be cut separately as the pressure Induced by cutting may initiate the development of color

- Mate the two films (A&B) dull side to dull side and lay them up directly against the circuit board (preferably adjacent to the cap layer of the center multilayer within a book). To confirm that the films have been paired correctly apply enough pressure to a small non-critical section to assure proper color development

- Place the book into a cold press and raise the pressure as normally done during lamination and hold for two minutes. The ideal temperature for testing is 74°F/23°C at 65% RH

- Break down book and Inspect PRESSPROBE™ FILM B to view amount and distribution of pressure applied to surfaces of contact

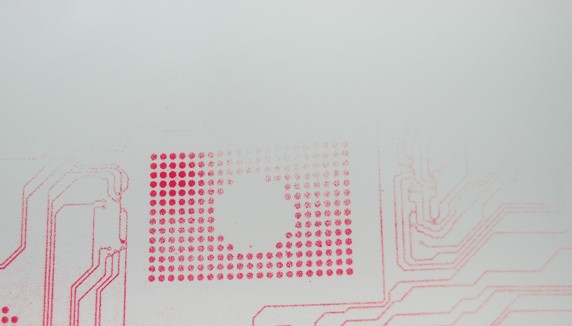

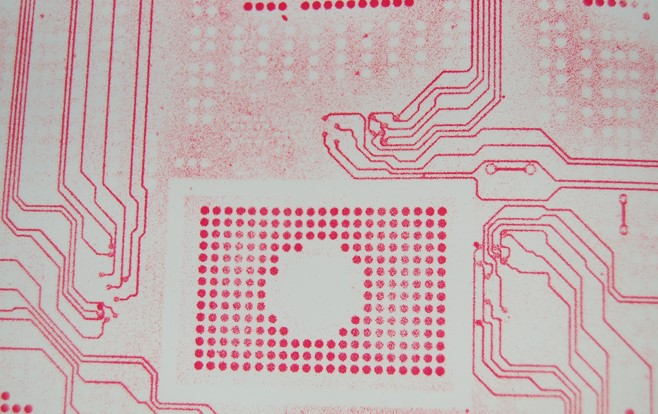

ACTUAL PRESSPROBE™ TEST RESULT

Hard lamination makeup with less than 10% compression from Press Pad:

Soft lamination makeup with greater than 40% compression from PACOPAD™:

The varying degrees of pink intensity shows the impact of high and low pressure equalization as a result of the compression value of the presspad being used. The soft make-up optimizes the inefficiencies of the lack of z-axis pressure distribution that can happen in a hard make up.