PACOPADS™:

PRESSURE EQUALIZATION PRESS PADS FOR LAMINATION OF FLEXIBLE AND MULTILAYER CIRCUIT BOARDS

OVERVIEW

PACOPADS™ are a line of press pads specifically engineered to improve the process of laminating rigid multi-layer and flexible Printed Circuit Boards. They serve two primary functions: to accurately control heat input and to equalize the pressure applied to the panel surface.

PACOPADS™ are a unique, cellulosic-based product, engineered specifically to meet the performance requirements of both Rigid Multilayer and Flexible Printed Circuit Board manufacture. PACOPADS™ are manufactured on a highly specialized paper machine, using virgin fibers that guarantee a low density profile consistent across the entire area of the sheet. (See Press Probe Illustration)

PACOPADS™ are vastly superior to commodity grade papers which vary significantly in weight, thickness, hard spots, contaminants, and moisture.

FEATURES

- Proven worldwide performance since 1986

- Operating temperature of 475°F/246°C for six hours

- Two standard thicknesses of .035" (.89mm) and .055" (1.4mm) for custom Heat Input Control and optimal Pressure Equalization

- Extremely low moisture to reduce liquid buildup in vacuum systems minimizing heat rise variability due to volatility

- Uniform fiber formation and distribution for unmatched pressure equalization, micro Z-axis conformance and repeatable, consistent Heat Rise

- Low fiber dusting and contamination

- No resinous binders or fillers, essentially sulfur free, with no odor or solvents to pollute vacuum systems or the work environment

- Environmentally friendly – suitable for re-pulping, land fill disposal or incineration

LAMINATION PROCESS ADVANTAGES

- Control of Heat Rise: PACOPADS™ perform this function with totally predictable and reproducible results due to their uniform fiber distribution, low moisture content and tightly controlled thickness and weight specifications

- Equalization of Pressure throughout the Pressure Load: Use of PACOPADS™ eliminates air voids, inner-layer slippage and white corners or edges. PACOPADS™ also reduce dielectric thickness variations, image and glass cloth transfer, and obviate the potential of low-pressure prepreg blisters

- 3-Dimensional Conformance: PACOPADS™ eliminate X-Y-Z axis stress which cause cover-layer voids and circuit distortion. At the same time, PACOPADS™ improve cavity fill, and adhesive flow control in the manufacture of Flex, Rigid-flex, and Heat Sink Circuit Boards

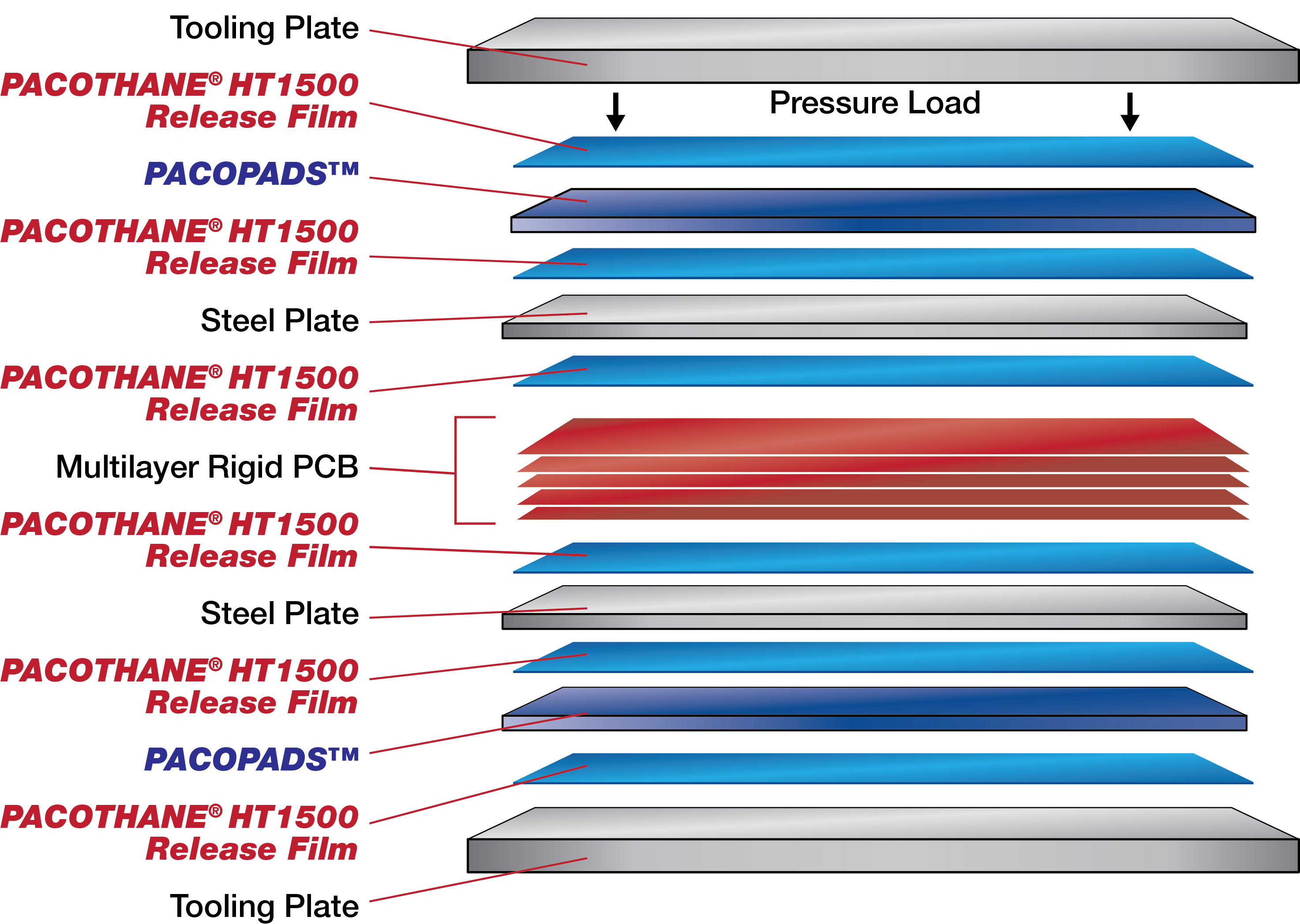

RECOMMENDED LAMINATION LAY-UP

needs to be added.....

DESCRIPTION OF STANDARDS

AVAILABILITY

PACOPADS™ are available in custom-made sheet sizes, tooled to customer specifications. The complete line of Pacothane Technologies products is available from leading local Distributors Worldwide who offer "Just in Time" delivery from locally-available stocks.

SAFETY