PACOTHERM™:

PRESSURE EQUALIZATION PRESS PADS FOR LAMINATION OF FLEXIBLE AND MULTILAYER CIRCUIT BOARDS

OVERVIEW

PACOTHERM™ (also called TRIPAK) is a PACOTHANE®-clad, releasable Press Pad that is specifically engineered to control the variables associated with the lamination processes used in the manufacture of Printed Circuit Boards. TRIPAK'S primary function is to economically deliver consistent, repeatable Heat Rise. The secondary function of this three-layer pad is to equalize applied pressure across the panel surface.

PACOTHERM™ TRIPAK is unique, and shares the exact same attributes and functionality as Pacopad only with the added benefit of bonded Pacothane Release Film on both sides. First manufactured on a highly specialized paper machine, using virgin fibers that guarantee a low density profile consistent across the entire area of the sheet the Pad is then carefully laminated on both sides with Pacothane Release Film exceeding in performance of any known "Multiple Use" Press Pad offering in the market. Tripak is an excellent High Temperature Press Pad for Rigid Polyimide Lamination being rated to 475°F without any functional risk.

LAMINATION PROCESS ADVANTAGES

- Control of Heat Rise: TRIPAK is specifically engineered with extremely exacting and tight Weight, Thickness, and Moisture parameters to guarantee repeatable Heat Rise through multiple press cycles

- Low Operating Cost: TRIPAK saves costs by reducing lay-up time and inventory cost. It is reusable depending on handling conditions, offering savings comparable to Kraft paper, Silicone Rubber, or other commodity Press Pads

- Excellent Pressure Equalization: TRIPAK is designed to be soft and Compressible to accommodate and equalize macro-pressure imbalance across the panel surface

FEATURES

- Single-ply handling, TRIPAK is a 3-ply construction with a custom-engineered Press Pad sandwiched between two layers of PACOTHANE® Release Film. This guarantees quick and clean release from Separator and Tooling Plate surfaces

- Static-free, clean and essentially fiber-free (cellulose fibers are "sealed" in between the two layers of PACOTHANE® Release Film)

- Optimized surfaces for automated handling Equipment

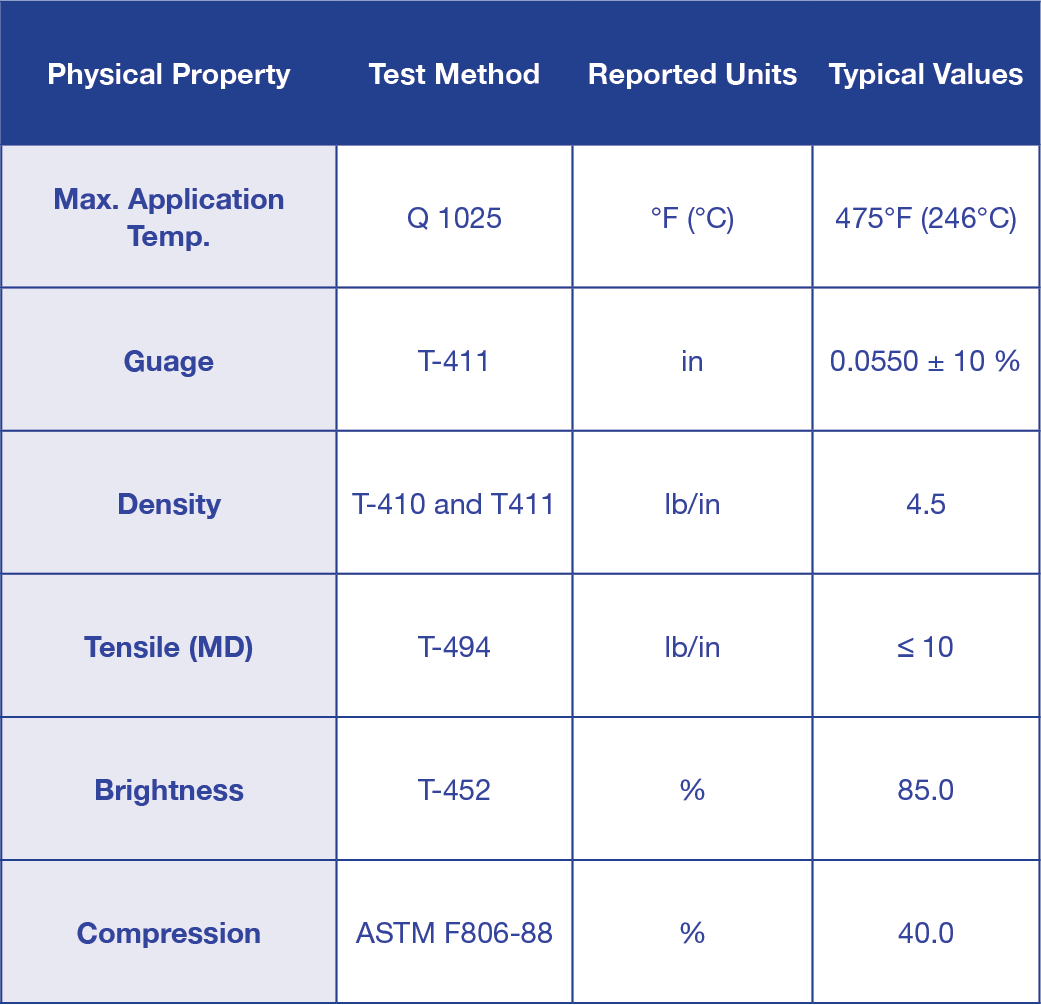

- Operating temperature of 475°F (246°C)

- Available in a selection of two thicknesses of .035" (0.89 mm) and .055" (1.4mm) for customized Heat Input control

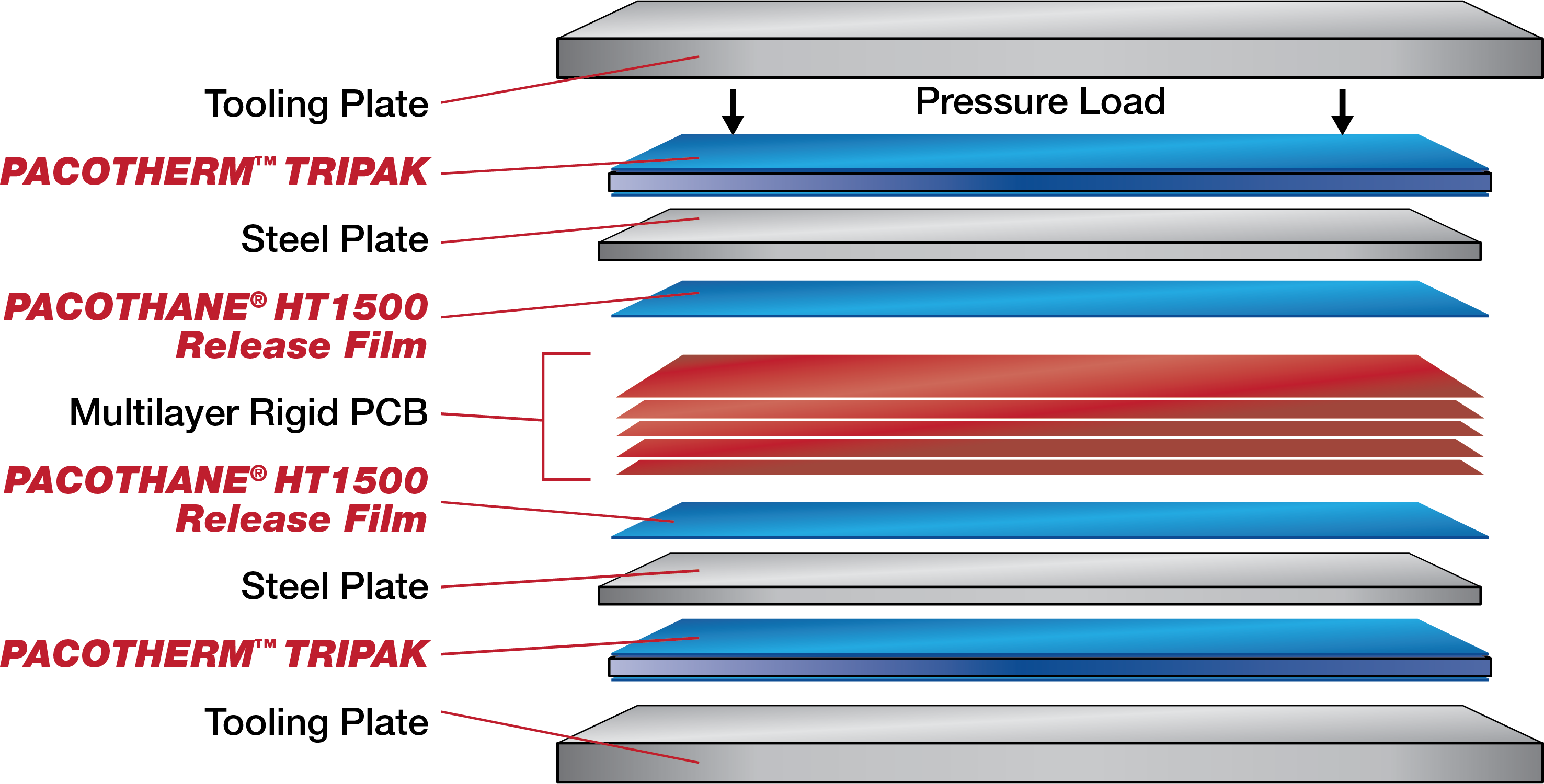

RECOMMENDED LAMINATION LAY-UP

DESCRIPTION OF STANDARDS

AVAILABILITY

PACOTHERM™ TRIPAK is always available in custom-sized sheets (with or without tooling holes) for "Just- In-Time" delivery through exclusive local Distributors around the world from locally-available stocks.