PACOFLEX™ 10000:

FOR LAMINATION OF COVERLAYS AND FLEXIBLE CIRCUITS

OVERVIEW

PACOFLEX™ 10000 is a single layer two-sided conformable release film that is available in a thickness of .0105"/267µ for cover-layer and flex circuit applications that require more hydraulic drive. This film must be used with a buffer release film positioned between the circuit and PACOFLEX™ 10000. The other side has a designed suitable release coating that allows it to be easily removed from separator plates or press pads.

LAMINATION PROCESS ADVANTAGES

- Total Elimination of Entrapped Air between the Cover-Layer and the Circuitized Base Laminate

- PACOFLEX™ 10000 delivers increased discreet hydraulic force to reliably drive the Cover-Layer into complete side-wall conformance with the Circuitized Base Laminate

- Finite Control of Adhesive Flow

- Due to the optimized surface, and superior conformability PACOFLEX™ 10000 dams back acrylic and epoxy adhesives from flowing into Cover-Layer clearance areas

- Quick, Easy, Contaminate-Free Release when used with proper release buffer sheet

- PACOFLEX™ 10000 "locks-in" around the Flexible components to minimize distortion due to Heat and Pressure

- PACOFLEX™ 10000 conforms closely to the part surface without excessive flow-out from the sheet. Deformed Circuits, Crushed Pads, and Glossy Pressure Spots are eliminated, resulting in repeatable Pad Registration due to the engineered Z-axis characteristics of the base hydraulic film

- Allows for Reduced Lamination Pressure in some applications

- PACOFLEX™ 10000, used with PACOPADS® Pressure Diffuser Pads, delivers unmatched Z-axis pressure equalization. These two companion products conform and stabilize the Flexible components allowing the user to study impact of reducing pressure force

FEATURES

- Two-sided direct coat release allows users to develop custom techniques as it relates to special Flex Lamination applications with the added benefit of increased hydraulic "Z" axis

- Engineered Conformance layer that prevents uncontrolled "squeeze-out"

- Smooth Surface Finish for superior Adhesive Flow Control

- Extremely low X-Y axis movement

- Clean, inert with no out-gassing of contaminants or solvents harmful to vacuum systems

- Operating temperature to 425°F/216°C with reduced ram pressures

- Environmentally friendly with no ozone-depleting chemicals or flourines

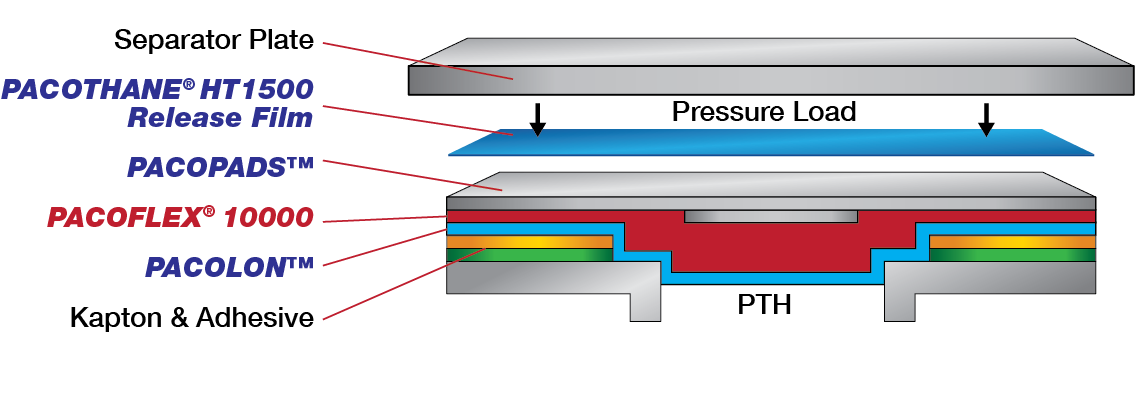

RECOMMENDED LAMINATION LAY-UP

DESCRIPTION OF STANDARDS

AVAILABILITY

PACOFLEX™ 10000 is available in custom-made sheet sizes, tooled to customer specifications. The complete line of Pacothane Technologies products are available from leading local Distributors Worldwide who offer "Just in Time" delivery from locally-available stocks.

SAFETY