PACO•VIA™ 3000:

A BLIND VIA HOLE LAMINATING FILM

OVERVIEW

PACO•VIA™ 3000 is a two-sided release film designed to be part of a Two-Component System (PACO•VIA™ 3000 and PACOPADS™) as a performance-driven line of High-Temperature, Resin-Blocking Release Films. The PACO•VIA™ 3000 System is specifically engineered to enhance sequential lamination of Buried and Blind Via designed rigid printed Circuit Boards.

LAMINATION PROCESS ADVANTAGES

- Resin Containment: PACO•VIA™ 3000 Resin-Blocking Film contains the resin within the via barrel eliminating the need for secondary processing to remove cured resin from the panel surface

- Barrel Fill: PACO•VIA™ 3000 Resin Blocking Film allows the liquid resin to essentially fill the via Barrel

- Contain Resin Squeeze-out: PACO•VIA™ 3000 contains resin squeeze-out like traditional release films while offering superior copper surface buffering from damaged Separator Plates

- Equalization of Pressure throughout the Pressure Load: The PACOPADS™ component of the PACO•VIA™ 3000 System ensures complete barrel fill, and controlled Dielectric Thickness. PACOPADS™ eliminate air voids, inner-layer slippage and white corners or edges. PACOPADS™ also reduce image and glass cloth Transfer, and alleviate the potential of low-pressure prepreg Blisters

FEATURES

- Two engineered Grades to fit all sequential lamination demands

- Choice of PACOPADS™ Pressure Equalizing Press Pads designed to suit all lamination process parameters

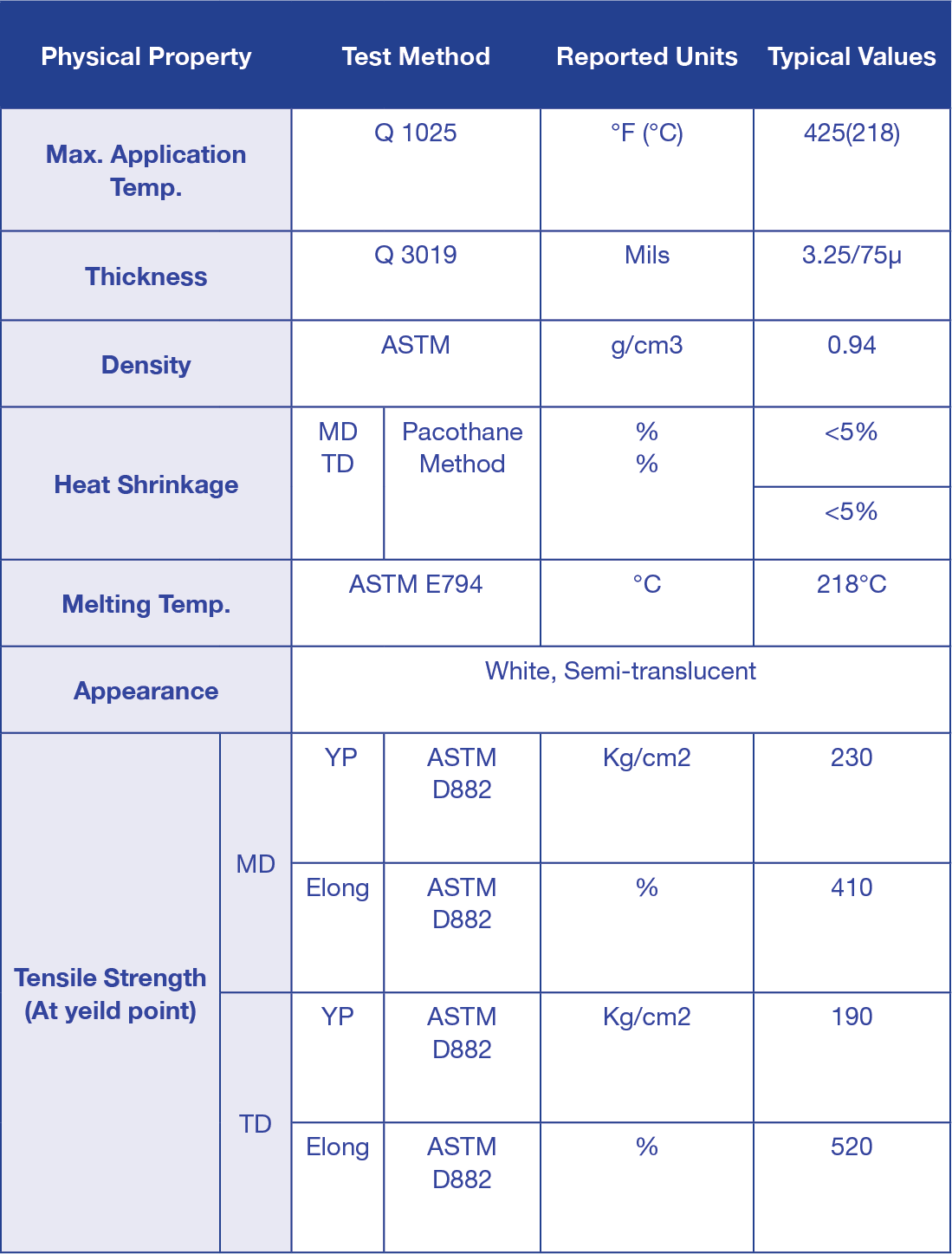

- Operating temperature of 425°F / 218°C for up to 4 hours

- Essentially inert, no out-gassing, plate residue, interlaminate adhesion influence, no vacuum system contamination

- Environmentally friendly: no chrome-depleting chemicals, no Fluorine’s

- The PACO•VIA™ 3000 System is designed to contain the resin flow within Blind Via Holes (onto adjacent copper-carrying layers) and to fill buried Via Barrels, under a wide range of Lamination Pressures (175-350 psi/12-24 kg/cm2), Hole Diameters (.004 to .040"/0.1 to 1.0mm), Heat Rises and Prepreg types

- The PACO•VIA™ 3000 System performs effectively well in Hydraulic and Hydraulic Vacuum-assist as well as with both stainless steel and aluminum Separator Plates. Steel is preferred

- The PACO•VIA™ 3000 System is suitable for all resin system types when laminated within the listed temperature constraints

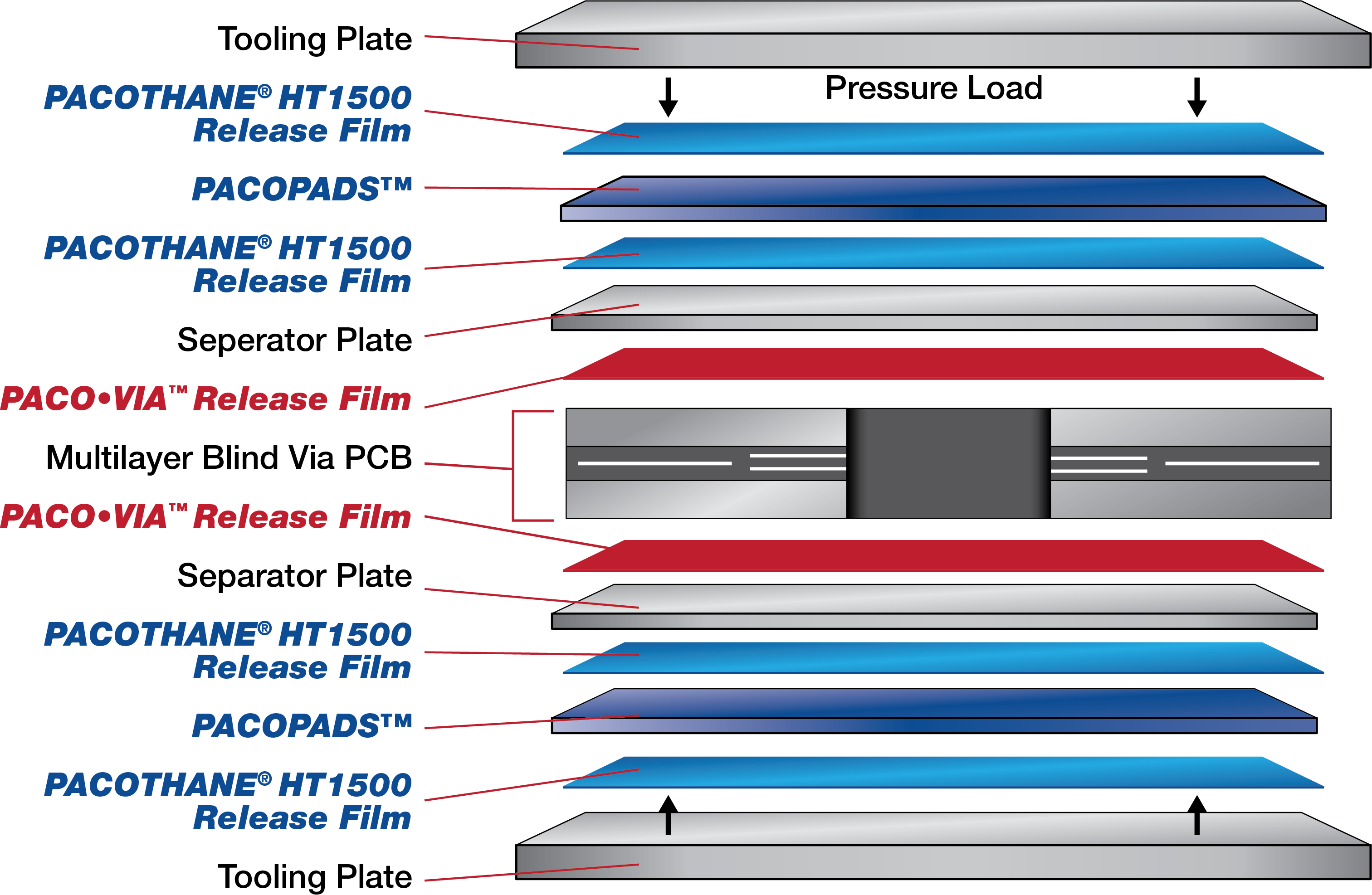

RECOMMENDED LAMINATION LAY-UP

needs to be added.....

DESCRIPTION OF STANDARDS

AVAILABILITY

PACO•VIA™ 3000 Conformal Release Film is available in rolls and in custom-made sheet sizes, tooled to customer specifications. The complete line of Pacothane Technologies products is available from leading local Distributors Worldwide who offer "Just in Time" delivery from locally-available stocks.

SAFETY